Industry knowledge about this item

How does hot melt adhesive web compare to solvent-based or water-based adhesives?

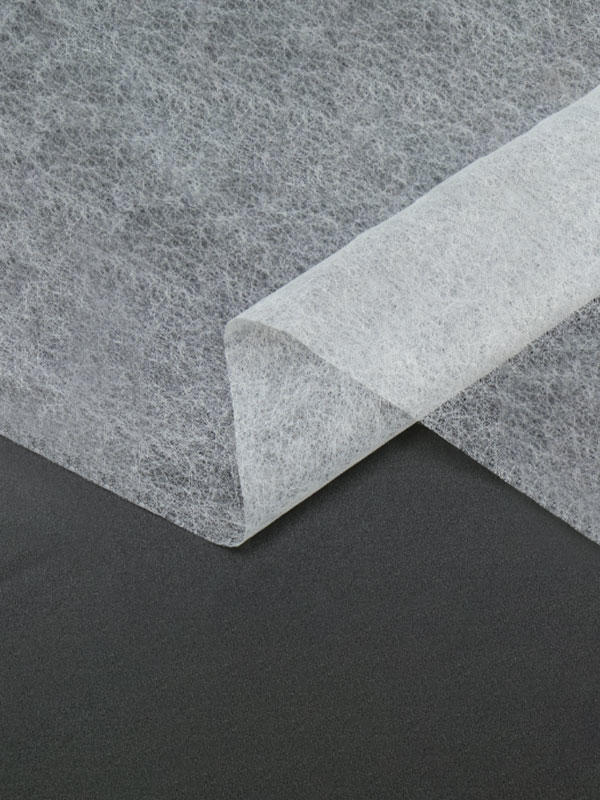

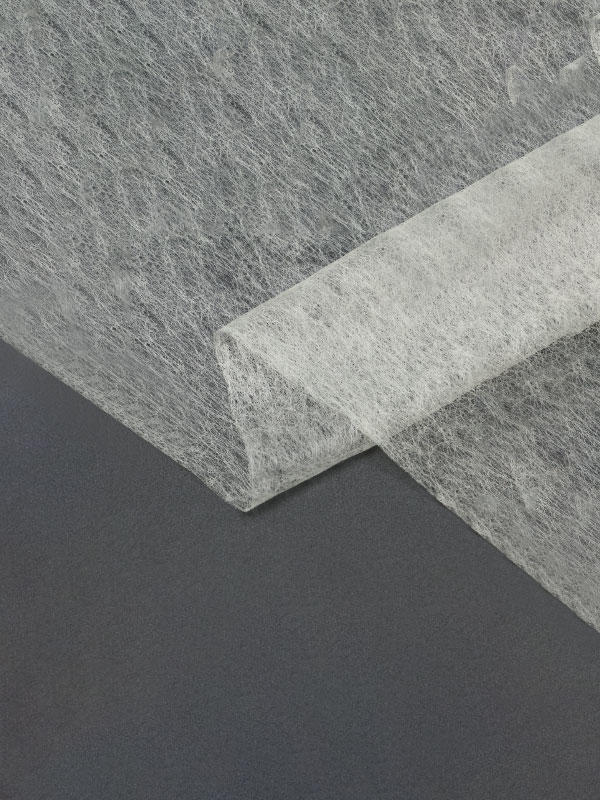

Composition: Hot melt adhesive web is typically a solid thermoplastic material that becomes molten when heated and solidifies upon cooling.

Application: It is commonly used in applications that require quick bonding, such as packaging, woodworking, textiles, and non-woven products.

Advantages: Hot melt adhesive webs offer fast setting times, immediate bond strength, and are often used in automated production processes due to their rapid curing nature.

Disadvantages: They may not perform well in high-temperature or high-stress environments since they can soften or melt under such conditions. They may also have limited flexibility compared to some other adhesive types.

Solvent-Based Adhesives:

Composition: Solvent-based adhesives contain a solvent that keeps the adhesive in a liquid or semi-liquid state until it is applied. The solvent evaporates upon application, leaving the adhesive to set.

Application: These adhesives are used in various industries including automotive, electronics, and construction.

Advantages: Solvent-based adhesives often provide good bond strength, flexibility, and resistance to environmental factors. They can also be used on porous and non-porous substrates.

Disadvantages: The use of solvents can pose environmental and health risks due to the release of volatile organic compounds (VOCs). The need for proper ventilation and handling precautions is important.

Water-Based Adhesives:

Composition: Water-based adhesives are formulated using water as a carrier for the adhesive components. They can be either natural (like starch or protein-based) or synthetic (like acrylic or latex-based).

Application: They are commonly used in paper, packaging, labeling, and woodworking industries.

Advantages: Water-based adhesives are generally considered environmentally friendly due to their low VOC emissions. They are versatile, offering good adhesion on a variety of substrates and flexibility in formulations.

Disadvantages: They may have longer drying times compared to other types of adhesives. They can also be sensitive to moisture during the curing process, which could affect their performance.

In summary, the choice between hot melt adhesive web, solvent-based adhesives, and water-based adhesives depends on the specific requirements of the application. Factors such as bond strength, flexibility, curing time, environmental considerations, and substrate compatibility will play a significant role in determining which adhesive type is the most suitable for a given project.

Is Hot melt adhesive tape suitable for bonding different types of materials?

Yes,

hot melt adhesive tape is generally suitable for bonding a wide variety of materials. Hot melt adhesive tape is made from a thermoplastic adhesive that becomes soft and molten when heated, allowing it to adhere to surfaces upon cooling and solidification. This type of tape is commonly used in industries such as packaging, manufacturing, and crafts due to its versatility and strong bond.

Hot melt adhesive tape can bond various types of materials, including:

Paper and Cardboard: Hot melt adhesive tape is commonly used in packaging applications to seal boxes and cartons. It adheres well to paper and cardboard surfaces.

Plastics: It can bond different types of plastics, such as polyethylene, polypropylene, and PVC, making it useful for plastic assembly and fabrication.

Wood: Hot melt adhesive tape can bond wood surfaces, making it suitable for woodworking projects and furniture assembly.

Fabrics and Textiles: It can bond fabrics and textiles, making it useful in the garment and textile industries.

Metal: While hot melt adhesive tape may not be as commonly used for metal bonding as other adhesive types, it can still be effective for certain applications.

Foam: Hot melt adhesive tape is often used to bond foam materials, such as in cushioning and packaging applications.

Glass: It can bond to glass surfaces, but the bond strength may vary depending on the specific type of glass and the conditions of use.