Industry knowledge about this item

How is PA Hot Melt Adhesive Web Applied?

Preparation: Ensure that the fabric pieces you want to bond together are clean and free from any dust, dirt, or contaminants. This will help achieve a strong bond.

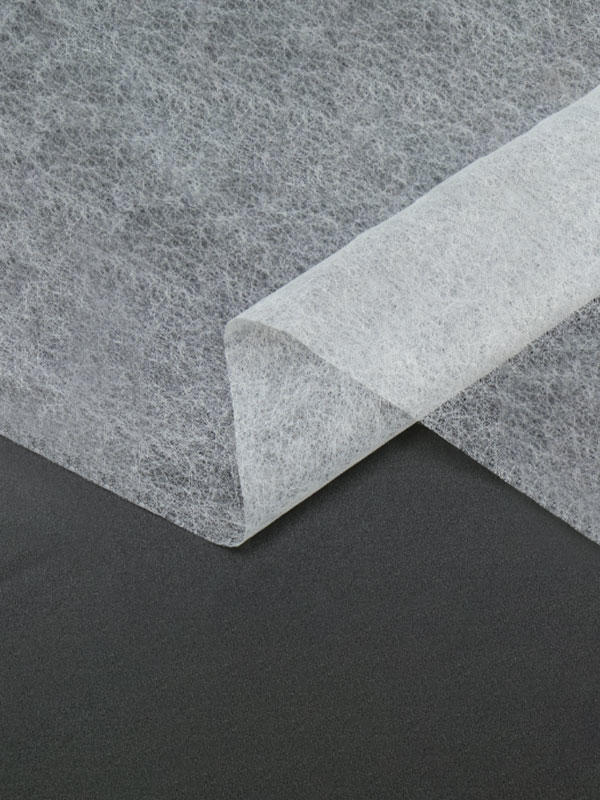

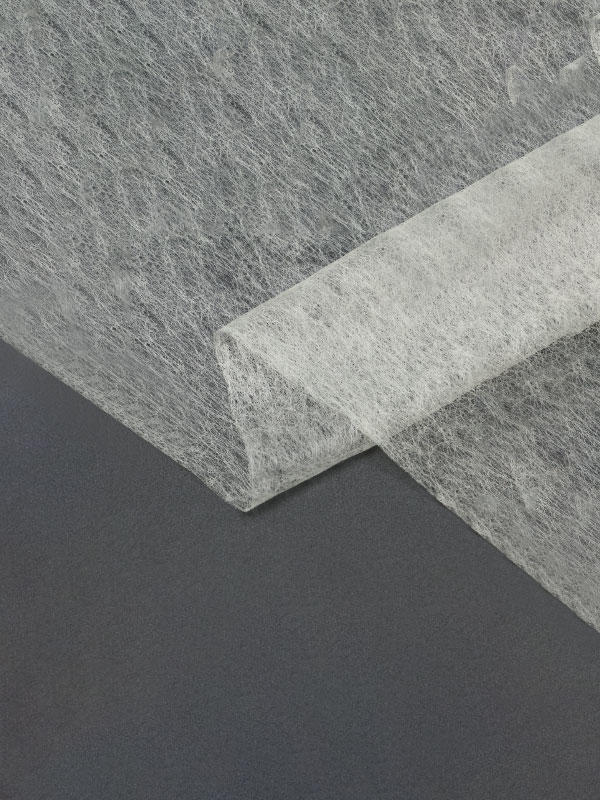

Cutting the Adhesive Web: The

PA Hot Melt Adhesive Web usually comes in rolls or sheets. You'll need to cut it into the desired shape and size to match the fabric pieces you're bonding.

Positioning: Place the adhesive web pieces between the layers of fabric where you want the bond to be formed. Make sure the adhesive is positioned evenly to cover the area you intend to bond.

Heat Application: Heat is required to activate the adhesive. This is typically done using a heat press machine. A heat press is a specialized device that applies heat and pressure evenly to the fabric and adhesive layers. The heat causes the adhesive to melt and flow, creating a strong bond as it cools and solidifies.

Pressing: Once the adhesive web is in place, the fabric stack is put into the heat press machine. The machine's heated plates will press down on the fabric and adhesive, applying even heat and pressure. The heat causes the adhesive to melt and penetrate the fabric fibers, creating a bond.

Cooling and Setting: After a specific amount of time (usually determined by the adhesive manufacturer's recommendations), the heat press is released, and the fabric is allowed to cool down. As the adhesive cools and solidifies, it forms a strong bond between the layers of fabric.

Quality Check: After the bonding process is complete and the fabric has cooled, it's a good idea to perform a quality check to ensure that the bond is secure and the fabric layers are properly adhered.

What industries commonly use hot melt adhesive web?

Textile and Apparel Industry:

Hot melt adhesive web is used for various applications in the textile and apparel industry, such as hemming, seam bonding, embroidery backing, and fabric laminations.

Automotive Industry: Hot melt adhesive web is used for interior trim bonding, headliner assembly, seat assembly, and other interior applications in the automotive industry.

Footwear Industry: In the production of shoes, hot melt adhesive web is used for bonding different shoe components together, such as attaching insoles, outsoles, and decorative elements.

Packaging Industry: Hot melt adhesive web is utilized in the packaging industry for carton sealing, case and box sealing, and attaching labels and tags to packages.

Furniture Industry: Hot melt adhesive web is used for bonding upholstery fabrics, attaching trimmings, and assembling furniture components.

Electronics Industry: Hot melt adhesive web can be found in electronics manufacturing for securing components, attaching wires, and encapsulating devices.

Medical and Healthcare Industry: Hot melt adhesive web is used in medical applications like dressing and wound care products, surgical drapes, and medical device assembly.

Hygiene Product Manufacturing: Hot melt adhesive web is used in the production of diapers, sanitary napkins, and other hygiene products for bonding various layers and components.

Construction Industry: Hot melt adhesive web is used in the construction of modular buildings, laminating building materials, and bonding insulation materials.

Aerospace Industry: In the aerospace industry, hot melt adhesive web is used for bonding lightweight materials, insulation, and interior components in aircraft.

Label and Tag Industry: Hot melt adhesive web is used for attaching labels and tags to various products, including clothing, food items, and consumer goods.

Sporting Goods Industry: Hot melt adhesive web is used for bonding materials in the production of sporting goods such as athletic shoes, apparel, and equipment.