OEKO-TEX 100.

Excellent bonding strength

Easy to use

skin-friendly and comfortable to wear

Matching fabric shrinkage after pressing

good washability

Processing:

- Cut the lining fabric to the right size according to your requirements.

- Place the lining between two pieces of fabric and iron the section for approx. 12 seconds.

- Allow it to cool for approximately 30 minutes to allow for bonding.

Condition:

Pressing temperature (°C): 160 - 170

Pressing pressure (kg/cm²)): 2.5-3.0

Pressing time (s): 10-18

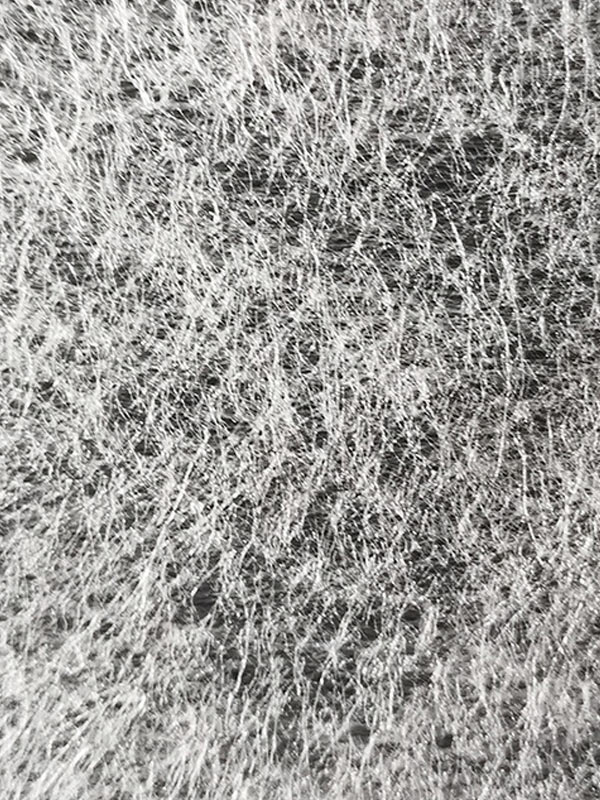

The basic structure of chemically bonded nonwoven interliningChemically bonded nonwoven interlining, as the name implies, is a nonwoven fabric formed by chemica...

1. High strength and wear resistance: Laying a solid foundationPolyester fibers are known for their high strength and excellent wear resistance, which provides ...

In the clothing manufacturing industry, collars, as an important part of clothing, not only carry decorative functions, but are also directly related to the wea...

In modern clothing manufacturing, every technological advancement has a profound impact on product quality, production efficiency and ultimate market competitiv...

In the vast field of the textile industry, spunbond nonwoven interlinings have become an indispensable part with their unique properties and wide application ar...

In the field of textiles, the hygroscopicity of weft insert knitted interlining is a crucial performance indicator. It is not only related to the comfort of wea...